■Press release

| |

||||||||||||||||||||

| 2024/08/20 | ||||||||||||||||||||

| To whomsoever it may concern. | ||||||||||||||||||||

| E-ThermoGentek Co.,Ltd. | ||||||||||||||||||||

| We have Successfully Developed and Prototyped Air-Cooled Stand-alone Power Supply System (S1-P3) Using Thermoelectric Generation! |

||||||||||||||||||||

| E-ThermoGentek Co., Ltd. (Headquarters: Kyoto City, CEO: Michio Okajima)

has successfully developed and prototyped the S1-P3 air-cooled stand-alone power supply system. This innovative system, created in collaboration with ENEOS Holdings,

Inc. (President: Tomohide Miyata), is designed for easy installation on

large-diameter waste heat pipes, such as those discharging steam or hot

drain water below 150°C from various industrial processes. The system can

generate thermoelectric power at 20-40W/m with a temperature differential

of 60-80°C and wind speeds of 2 m/sec, marking a “world’s first” in its class. A demonstration unit of this system is now available for viewing at our R&D facility at Osaka University. 【Background】 As global efforts towards decarbonization intensify, reducing greenhouse gas (GHG) emissions has become a critical challenge. A significant portion of waste heat is below 300°C, prompting increased interest in harnessing this low-temperature waste heat. E-ThermoGentek, with support from the New Energy and Industrial Technology Development Organization (NEDO), successfully developed and commercialized the flexible thermoelectric generation module "Flexiina?" in 2021 (Basic Patent: No. 5228160). This module offers a practical cost-performance ratio for converting low-temperature waste heat into electrical energy and has attracted substantial interest, with over 500 customer inquiries. |

||||||||||||||||||||

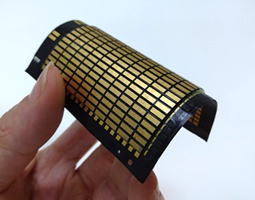

Figure 1."FlexiinaⓇ" module |

||||||||||||||||||||

| While thermoelectric generation has long been studied, traditional modules typically use ceramic substrates, which are hard and hence are inefficient at transferring heat from round shaped waste sources, especially for low-temperature waste. In contrast, the flexible "FlexiinaⓇ" module can conform to heat source pipes, enhancing heat recovery efficiency. Since semiconductor technology is utilized, cost-effective mass production and high reliability are achieved. 【Contents of this News Release】 This announcement focuses on the utilization of low-temperature waste heat sources below 300°C, specifically targeting steam and hot drain water from various factories, such as chemical and steel manufacturers, which are discharged at temperatures below 150°C. These types of waste are commonly released in large volumes through piping with diameters ranging from 20 to 30 cm. As shown in Fig.2, we have developed the air-cooled stand-alone power supply system (S1-P3), which incorporates our proprietary flexible thermoelectric generation module, "Flexiina?," with integrated heat-dissipating fins. This innovative power generation unit can be easily wrapped around and attached to large-diameter pipes, allowing for simple, compact, and cost-effective generation of power at a W-class level. |

||||||||||||||||||||

Figure 2: External view of the air-cooled independent power supply system (S1-P3) |

||||||||||||||||||||

| We installed this stand-alone power supply system on the thermal drain

water pipes at the Nakajo Oil Works of JX Nippon Oil & Energy Corporation,

a related company of ENEOS, as shown in Figure 3. Over the course of one

year, we conducted a Proof of Concept (PoC) to validate the system's performance.

During this period, the thermoelectric power generated was used to operate

surveillance cameras, LED lighting, and various IoT sensors. The system

was configured to transmit data from these devices via communication equipment

to our R&D facility at Osaka University for monitoring. The results confirmed that the system could achieve an output of 20-40W/m with a temperature difference of 60-80°C and a wind speed of 2 m/sec. |

||||||||||||||||||||

Fig.3 Demonstration experiment at JX Nippon Oil & Gas Exploration Corporation |

||||||||||||||||||||

| Following the PoC, we addressed various challenges identified during the

validation phase and developed a prototype of the air-cooled stand-alone power supply system (S1-P3), as shown in Figure 4. This prototype has been installed as a demonstration

system at our R&D facility at Osaka University. |

||||||||||||||||||||

Fig.4 Demo system at our R&D base in Osaka University |

||||||||||||||||||||

| 【Features】 The air-cooled stand-alone power supply system (S1-P3) presented offers several notable features: |

||||||||||||||||||||

| * | Easy Installation: Can be easily mounted on pipes carrying steam or thermal drain water below 150°C, enabling power recovery in locations where laying cables is challenging. |

|||||||||||||||||||

| * | Flexible Usage: Suitable for powering surveillance cameras, lighting, and other equipment.

It also supports the installation of numerous wireless sensors for data

collection, facilitating predictive maintenance, safety, and stable operations

in factories. |

|||||||||||||||||||

| * | Cost Efficiency: Compared to conventional binary power generation systems for low-temperature

waste heat, this system requires significantly smaller investment and maintenance

costs, providing a substantial advantage. |

|||||||||||||||||||

| Key Features of the Air-Cooled stand-alone Power Supply System (S1-P3): |

||||||||||||||||||||

| * | Easy Mounting: Easily attaches to pipes carrying waste steam or thermal drain water, allowing for efficient power recovery. |

|||||||||||||||||||

| * | No Expensive Cables: Eliminates the need for costly power cable installation, enabling power

generation even outdoors. |

|||||||||||||||||||

| * | Natural Air Cooling: Operates without the need for water-cooling pipes. |

|||||||||||||||||||

| * | Scalable: Easily adjustable in number (expandable or reducible), offering excellent scalability. |

|||||||||||||||||||

| * | Low Investment and Maintenance Costs: Requires minimal setup and ongoing maintenance expenses. | |||||||||||||||||||

| 【Product Specifications】 The specifications for the air-cooled stand-alone power supply system (S1-P3) at an indoor evaluation level are detailed in Table 1. Additionally, the power circuit configuration is illustrated in Figure 5, and the configuration of power generation system is shown in Figure 6. |

||||||||||||||||||||

Table1: Specifications for Air-Cooled Standalone Power Supply System S1-P3

|

||||||||||||||||||||

Fig. 5 Power supply circuit configuration  Fig.6 Configuration of Power generation system |

||||||||||||||||||||

| 【Impact of Outdoor Environment】 When used outdoors, the system can enhance its cooling effect by grounding the heat-dissipating fins, which increases cooling efficiency and, consequently, the output. Additionally, with typical wind speeds of around 2 m/s, the output is further improved. Fig.7 presents the results of an indoor laboratory investigation into the impact of wind speed. At a temperature difference of 60°C between the heat source pipe and the surrounding environment, and with a wind speed of 2 m/sec, the output was approximately 1.7 times higher compared to a no-wind condition. |

||||||||||||||||||||

(Heat source pipe temperature - Ambient temperature difference: 60°C; Output under no wind condition is considered as 1) Figure 7: Investigation of Wind Effects in an Indoor Laboratory |

||||||||||||||||||||

| 【Future Prospects】 E-ThermoGentek plans to actively market the air-cooled stand-alone power supply system (S1-P3) to customers interested in harnessing the vast amounts of steam and hot drain water below 150°C discharged from various manufacturing plants. The focus will be on using this system to power surveillance cameras, lighting, and IoT devices. We will propose Proof of Concept (PoC) trials tailored to meet customer needs. The S1-P3 system also has promising applications for thermoelectric power generation using thermal steam and thermal drain water from hot springs and geothermal power plants. In remote areas such as mountainous regions with hot springs, where electricity grid installation is costly and hazardous, there is a growing demand for stand-alone power systems powered by environmental energy. This system is expected to be highly effective in providing power in such areas where conventional power supply is challenging. However, power generation systems operating in remote locations require high reliability and maintainability. To address this, we are currently developing a secondary battery system equipped with a Battery Management System (BMS) designed to improve corrosion resistance and enhance maintainability, with support from NEDO. Once a reliable secondary battery system with a BMS is established, as illustrated in Figure 8, it is expected to play a crucial role as a power unit at the community level. By combining it with other environmental power generation systems like solar energy and secondary battery systems for electric vehicles (EVs), this system could significantly contribute to the advancement of decentralized power systems such as virtual power plants (VPP), which are anticipated to gain popularity in the coming years. |

||||||||||||||||||||

|

||||||||||||||||||||

| In this development, we focused on creating a stand-alone power supply

capable of generating W-class power for applications such as surveillance

cameras, lighting, and IoT devices. However, by optimizing the configuration

of the power generation unit to recover even more waste heat, it is possible

to scale up the system for energy-saving applications that require larger

power outputs. Through future marketing activities, we intend to identify

and address various customer needs. As demonstrated, the air-cooled stand-alone power supply system (S1-P3) offers the advantage of low initial investment and maintenance costs, making it a viable option not only for industrial waste heat recovery but also as a power generation system that can contribute to local economies. In the context of growing demand for sustainable solutions aligned with the SDGs, the S1-P3 system is expected to play a significant role in realizing a low-carbon, circular economy by effectively utilizing previously untapped heat sources. |

||||||||||||||||||||

★記事;http://www.e-thermo.co.jp/pr20240830_en.pdf |

||||||||||||||||||||

<Contact for inquiries regarding this matter>

|

||||||||||||||||||||

E-ThermoGentek Co., Ltd.

【Head Office】

601-8047 102 Kujo CID Building, 13 Higashikujo Shimotonoda-cho, Minami-ku,

Kyoto

E-mail ![]()