Product

|

|||

| ≫ Thermoelectric power generation business | ≫ Catalog download |

● Thermoelectric power generation business

Background

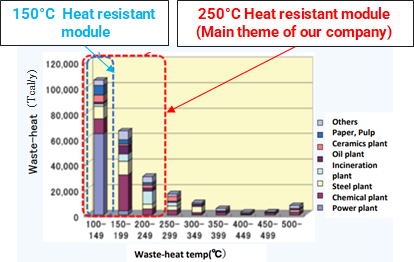

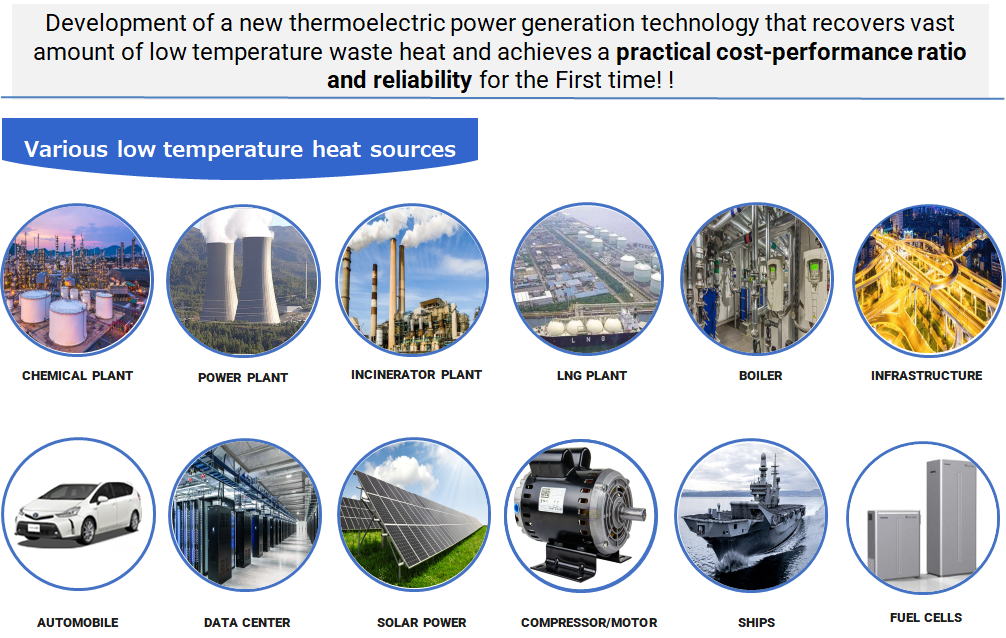

● Exhaust(waste) heat, which is released into the environment in significant volumes, consumes more than 60% of the primary energy utilized in the world! ! !→ 75% of the exhaust heat is low-temperature exhaust heat or heat produced below 300℃.

(High-temperature exhaust heat is commercialized via steam recovery technology. )

→ Compact and easy-to-use thermoelectric power generation that converts waste heat directly into electricity is gaining popularity as a way to advance the SDGs

Current status of unused low-temp. exhaust heat. (Amount of waste heat by industry and temperature) Source) Research and Development Strategy Center, Science and Technology Agency, Science and Technology Future Strategy Workshop Report CRDS-FY2012-WR-03 "Development of basic technology for innovation in medium and low temperature heat supply and demand" 25p |

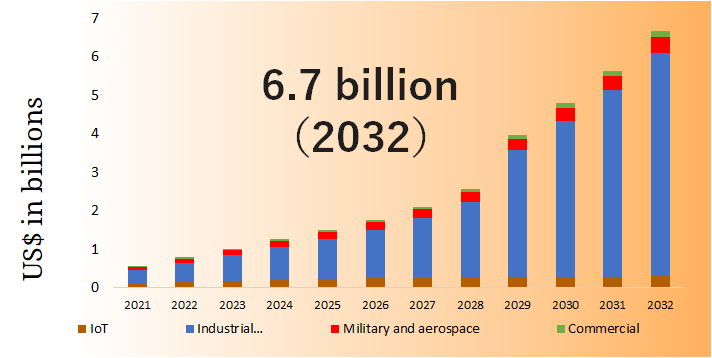

Forecast of thermoelectric power harvesting market by IDTechEx Source) Dr. P.Harrop,R.Das “Thermoelectric Energy Harvesting 2022-2042”, IDTechEx (2021) |

|

Our Proprietary Technology

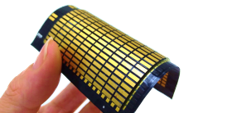

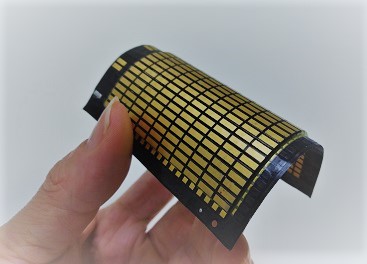

| Commercialization of the flexible thermoelectric power generation module

"FlexiinaⓇ"! ( World’s First ever !) 【Novelty】 Module structure (Basic Patent;Patent no.5228160, obtained a US patent as well) ■ High energy recovery efficiency is made possible by flexible module structures that are freely bendable and can be closely attached to cylindrical heat sources → Elevated performance ■ High-speed, high-density assembly of existing BITE thermoelectric components on ultra-thin flexible substrates using semiconductor technology → Huge demand makes it possible to reduce the cost!! Received inquiries from over 500 companies!! |

||

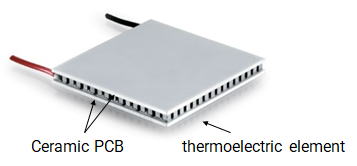

| Conventional thermoelectric power generation module  <Thick and Rigid> |

|

Standard sample of Flexible thermoelectric power generation module “Flexiina Ⓡ”  |

Unique thermoelectric power generation element technology

Flexiina🄬, equipped with unique thermoelectric generationelements that can accommodate various low temperature heat sources

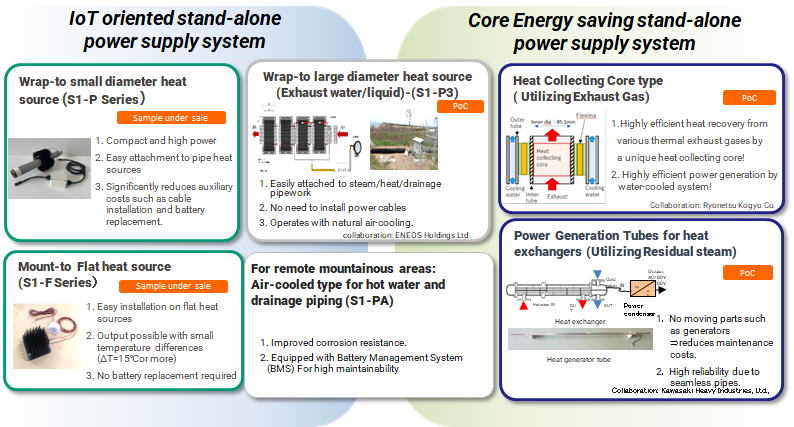

Waste Heat-Powered stand-alone Power Supply S1-P&Fseries

| Sample under sale |

Catalog download |

|

Achieve superior heat recovery from cylindrical and flat heat sources! We offer compact, high-output autonomous power sources tailored for IoT applications! ・Available in pipe-wrap, flat, and finless configurations ・Suitable as a power source for various IoT sensors, providing an output of 1mW or more with a temperature difference of 15-35°C between the heat source and the surrounding environment. ・Applied for Explosion-proof certification , which will offer enhanced safety features 〔Features〕 ➊ No need for battery replacements Drastically cuts down on maintenance and management expenses ➋ Offers high output with outstanding cost-effectiveness Perfectly suited for high-frequency sampling, sensing at elevated vibration frequencies, and predictive failure analysis ➌ Compact and easy to install Streamlines the process of exploring and integrating new IoT systems |

||

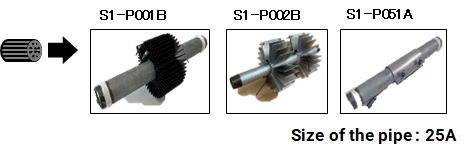

stand-alone Power Supply S1series

| S1-P001B:10mW(3.3/5V) | S1-P002B:180mW(9/12V) |

|

|

| <<Sample under sale>> | |

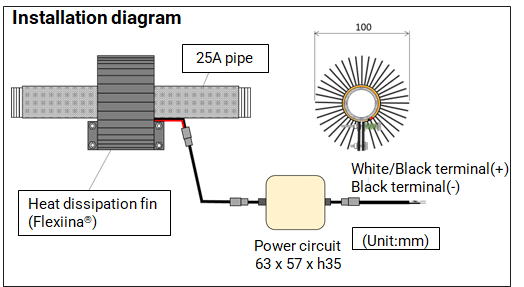

Installation drawing

|

|

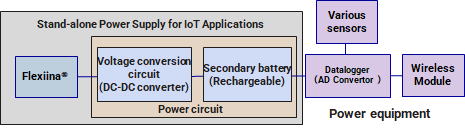

Flexiina®product configuration and power equipment connection

|

|||||

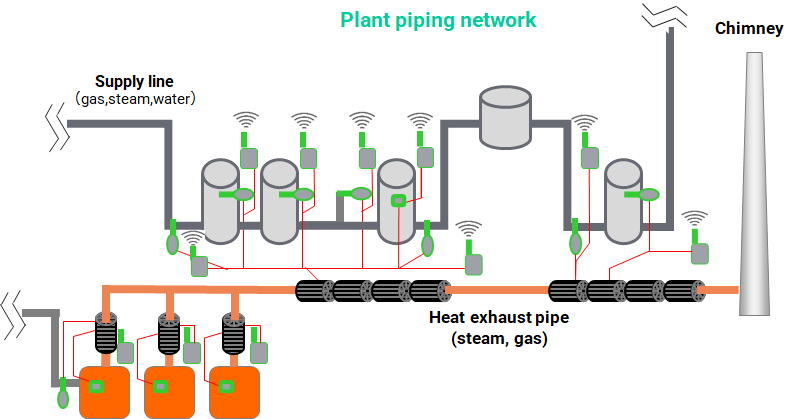

Installation example of Sensor and stand-alone power supplies for industrial plants

|

|||||

|

|

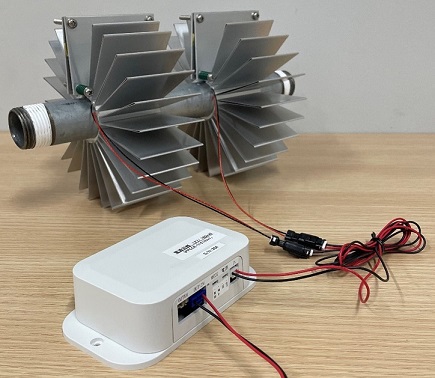

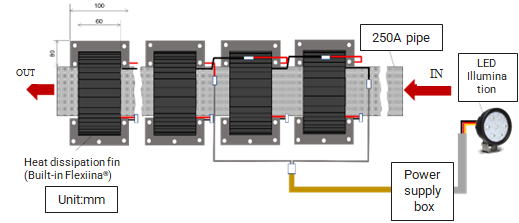

Stand-alone power supply utilizing residual heat from hot water S1-P3

| 〔Features〕 ➊ Electricity production from effluent that was previously unusable. ➋ Electricity can be easily harvested even outdoors.(no need to install electric wires, which was an issue in the past due to the cost incurred) ❸ Works with air cooling. (water cooling and thereby pipe laying costs are eliminated) 〔Specification〕 Output: 24V, 20-40W/m ΔT (Heat source and ambient):60℃-80℃ Pipe diameter :φ267.4mm (250A), (ground contact) 〔Application〕 Lighting, surveillance camera, various sensors, communication systems etc. |

|

Installation drawing

|

|

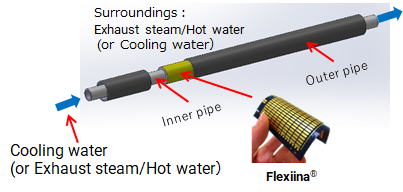

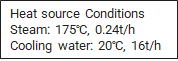

Double-tube thermoelectric generator utilizing steam

S2-Wseries

| 〔Features〕 ➊ Excellent cost performance: - High heat recovery efficiency due to unique structure and manufacturing method - Significantly reduces maintenance costs as there are no moving parts like generators - Electricity generation is feasible even from minimal steam (0.2 t/h). ➋ High reliability and high-pressure resistance due to seamless pipes. ❸ High degree of design freedom (supports a wide range of heat source sizes) 〔Specification〕 Output : 1unit; 6kW ※150W/tube×40tubes ★Installation example 7units;Approx 40kW(AC100/200V) 〔Application〕 Factory Power (Control panel, peripheral devices, emergency power supply, etc.) 〔Cost Target〕 Mass Production : Pay back period of 5 years (utilizing energy-saving subsidies) |

Double tube Heat exchanger with power generation

| "Thermoelectric heat exchanger tubes" for tube heat exchangers ※Long:1.6m、Output:150W    |

Installation drawing

|

|

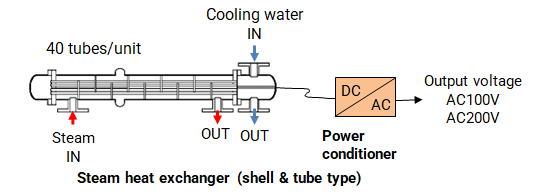

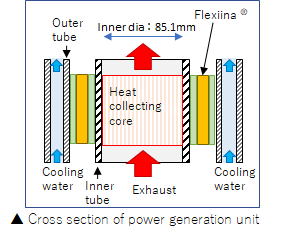

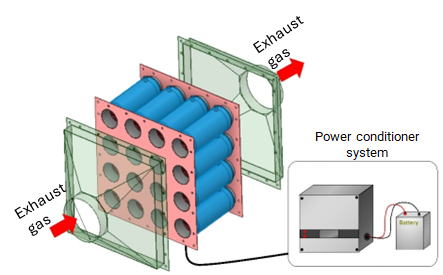

Thermoelectric power generation tube with built-in heat collection core utilizing exhaust gas heat S2-Cseries

| 〔Features〕 ➊ High-efficiency heat recovery from exhaust waste heat due to the unique structure of the built-in heat collection core and the "FlexiinaⓇ". - Low maintenance cost as there are no moving parts ➋ Air-cooling is also possible in places where water cooling is difficult. ❸ The number of units can be changed to accommodate a wide range of heat source sizes. 〔Specification of Water-cooled type〕 Output : 1.5 kW ※100W/tube×16tube (AC100/200V) 〔Application〕 Factory Power (Control panel, peripheral devices, emergency power supply, etc.) 〔Cost Target〕 Mass Production : Pay back period of 5 years (utilizing energy-saving subsidies) 〔Core Technology〕 |

|

Thermoelectric generation tube with built-in heat collection core   |

Example of exhaust duct for water-cooled power generation system configuration

|

|

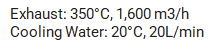

Competitive Landscape

|

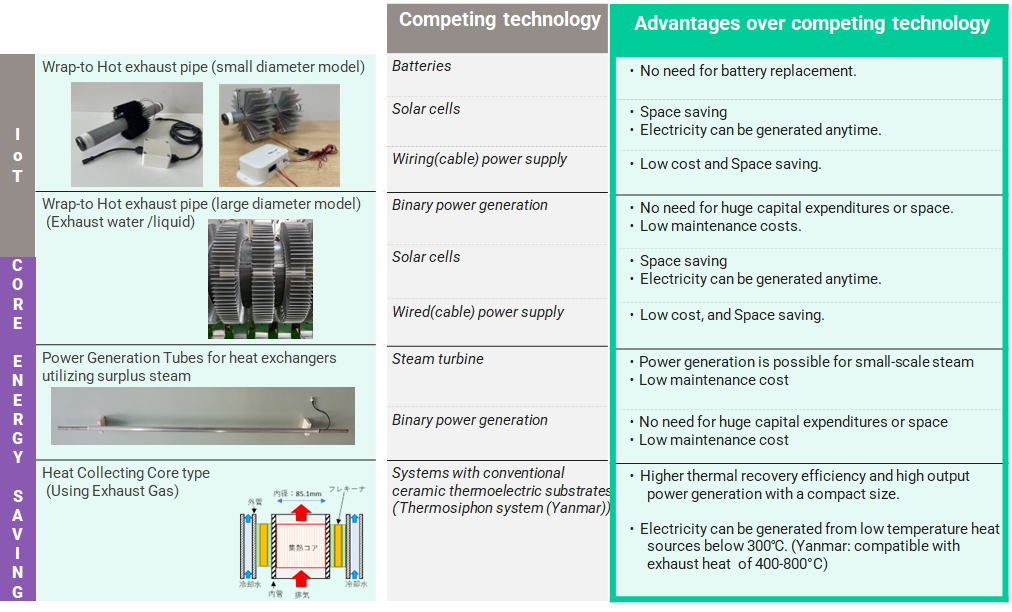

Future vision

| Energy management system with the concept of ‘Local production for local consumption’ using residual heat |

|

|

E-ThermoGentek Co., Ltd.

【Head Office】

601-8047 102 Kujo CID Building, 13 Higashikujo Shimotonoda-cho, Minami-ku,

Kyoto

E-mail ![]()